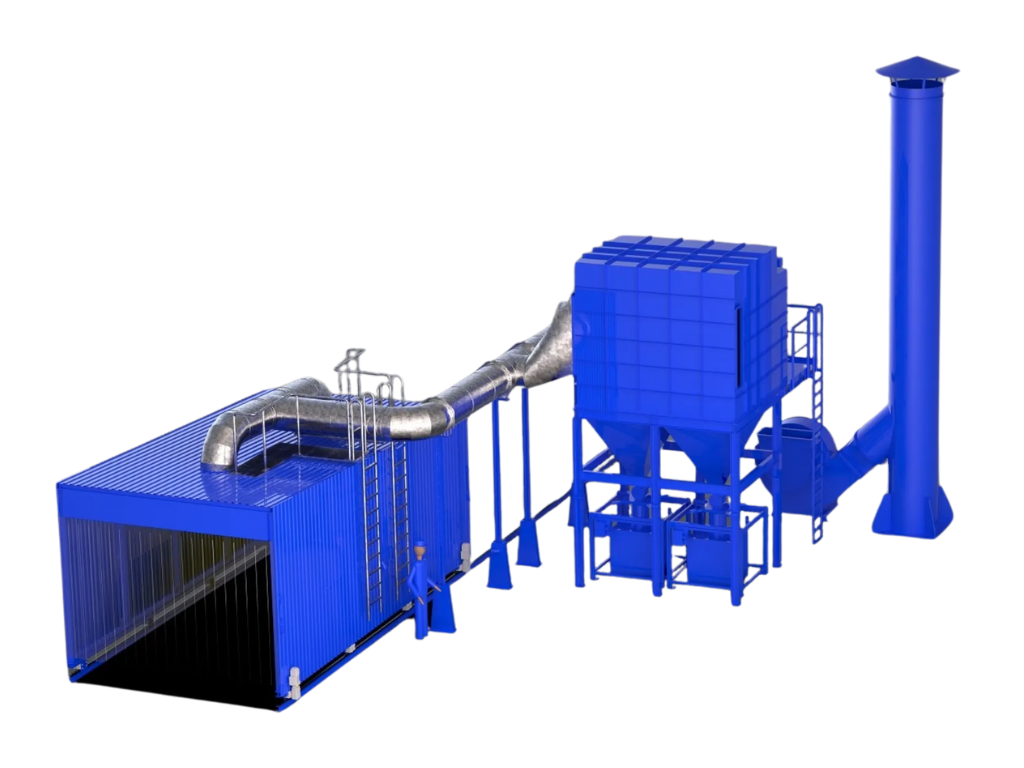

Mobile and stationary flame cutting extraction halls

When cutting with fuel gases, particularly propane or acetylene, combined with oxygen, large and bulky machine parts or complex structures are reduced to manageable pieces on recycling yards. These materials, due to their size, shape, or material properties, cannot be processed with conventional cutting tools like shears. This specialized cutting process has become indispensable in the recycling industry, especially when it comes to efficiently and safely dismantling hard-to-reach or extremely robust components.

However, this cutting process produces significant amounts of smoke gases containing iron, iron oxide, and trace amounts of hydrocarbon compounds. These gases result in the formation of noticeable yellow to ochre-colored smoke clouds, which not only degrade air quality in the immediate area but can also have far-reaching effects on the environment and the health of people working or living near such facilities. The complexity of these smoke gases, which arise from the thermal decomposition of materials and the chemical reactions occurring during the cutting process, poses a particular challenge for environmental engineering. The composition of these gases can vary depending on the type of material being cut and the specific conditions of the cutting process, making effective management essential.

With the introduction of the new Technical Instructions on Air Quality Control (TA Luft) in August 2022, operators of scrap processing facilities face new regulatory requirements. The TA Luft, a binding regulation for facility operations in Germany, sets stricter emission limits and mandates several measures to protect air quality. One of the key updates concerns the cutting of metals, particularly with cutting torches. The regulation stipulates that the gases and smoke produced during this process can no longer be released unfiltered into the atmosphere. Instead, they must be captured and filtered by appropriate exhaust gas purification systems to minimize pollutant emissions and ensure compliance with the new limits.

Oberländer, a company well-known for its expertise in air purification systems and mobile hoods for tipping boxes, has responded to these new challenges. In collaboration with the renowned manufacturer DEMAG, known for its powerful and reliable crane systems, Oberländer has developed innovative solutions specifically tailored to the needs of the scrap processing industry. These new systems offer a cost-effective alternative to the large-scale systems currently available on the market and are particularly suited for small to medium-sized operations that may not have the financial resources or space to install large exhaust gas purification systems.

Oberländer’s concept involves the development of modular air purification systems that can be flexibly adapted to the specific conditions on site. These systems are not only compact and space-saving but also easy to install and maintain. Moreover, they provide high efficiency in pollutant removal, enabling operators to meet the requirements of TA Luft without difficulty. This concept is complemented by mobile hoods, which allow for targeted capture of the smoke gases directly at the cutting site, and the integration of DEMAG’s robust and versatile crane systems, which facilitate the transport and positioning of materials to be cut.

Overall, Oberländer’s new solutions represent a groundbreaking development in air purification technology, which not only meets legal requirements but also contributes significantly to environmental protection. They provide scrap processing facility operators with the opportunity to make their processes more environmentally friendly and efficient without sacrificing economic viability.

If you would like to learn more about these innovative systems or understand the specific benefits for your operation, we are always available to assist you. Our experienced team offers personalized consultations and will work with you to develop custom solutions tailored to your specific needs. Do not hesitate to contact us—we look forward to supporting you in implementing the new regulatory requirements and working together towards a more environmentally friendly future.