Scrap Baling Presses

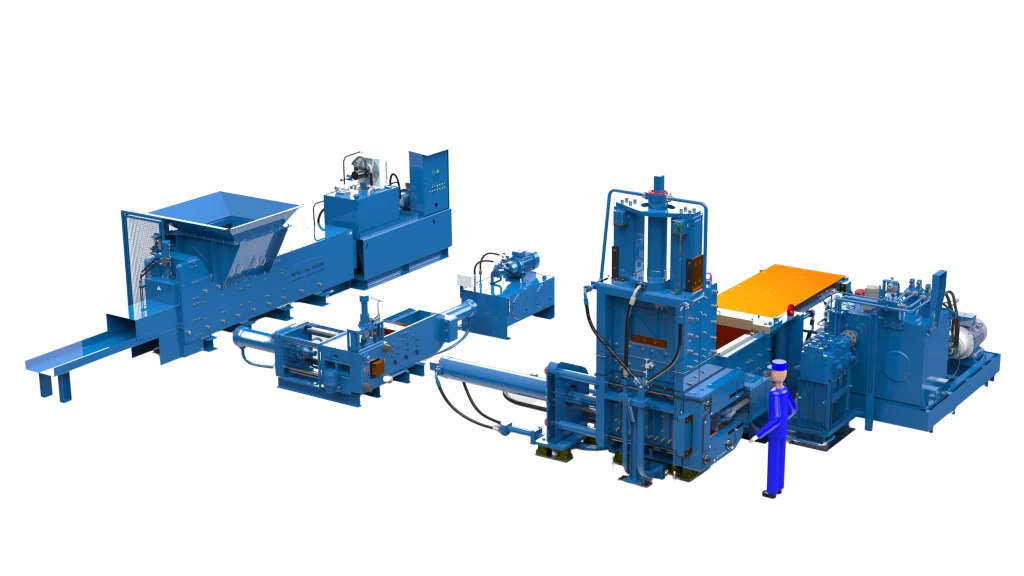

In addition to press shears, pure scrap baling presses in various sizes and designs are also offered for the production of scrap packages. Starting with simple two-compressor presses for thin-walled production residues or cans, through to multiple-compressor presses with hinged lids for bulky mixed scrap.

Depending on the type of scrap, maximum edge length and the later use of the bales, the scrap baling presses are selected for the customer.

Due to the high level of reliability and compaction of Oberländer scrap baling presses, in addition to the classic operation as a “stand-alone” at the recycling yard, direct integration into production systems is also possible, so that the resulting scrap is compacted directly in line in order to reduce volume. Such baling presses are found in press shops in the automotive industry, the sheet metal processing industry, or the non-ferrous metal processing industry.

In addition to the pure baling press, loading units such as plate conveyors and tipping trough scales, as well as scrap package handling and stacking systems, can also be offered.

The automatic storage or stacking of bales on pallets, in railroad wagons or containers is a prerequisite for efficient recycling in industrial companies.

When it comes to complete packaging systems, the focus is on automation so that operating costs and availability can be optimized. Oberländer Recycling Machines can offer all of this as a complete solution.

Ask us about your special solution.

Based on many years of experience, different scrap baling presses are offered in terms of pressing force, size and baling performance based on knowledge of the raw materials, quantities and later use of the bales.

The Oberländer baling presses are characterized by high pressing forces, which compact the scrap into a rigid bale to avoid disaggregation even after intense handling operations. The use of compactors or hinged lids equipped with shear blades also ensures that protruding parts of large-volume scrap are cut off cleanly to produce clean bale edges.

| Type | Model | Press box dimensions | Bale size | Press force |

|---|---|---|---|---|

| P2 H 1000/500-2x2 | 2-Compactor Press | 1.0 x 0.5 x 0.3 m | 300 x 300 mm | 80 t |

| P3 HV 1900/1250-3x3 | 3-Compactor Press | 1.9 x 1.25 x 1.0 m | 300 x 300 mm | 180 t |

| P2 H 1900/1000-4x4 | 2-Compactor Press | 1.9 x 1.0 x 0.4 m | 400 x 400 mm | 260 t |

| P3 HV 2750/1450-4x4 | 3-Compactor Press | 2.75 x 1.45 x 1.0 m | 400 x 400 mm | 320 t |

| P3 HVK 5000/2000-5x5 | 3-Compactor + Lid | 5.0 x 2.0 x 1.0 m | 500 x 500 mm | 500 t |

| Smaller balers can also be offered in mobile versions. | ||||

| The presses are available in different hydraulic sizes to suit various bale capacities. | ||||