Special Shears for production companies

The product range also includes special scrap shears and presses for production companies to shred or compact waste and material residues on site. This saves logistics costs and increases revenue. The systems are adapted for production operations and can be loaded with existing handling equipment (forklifts or indoor cranes) and work fully automatically.

These shears/presses are, for example:

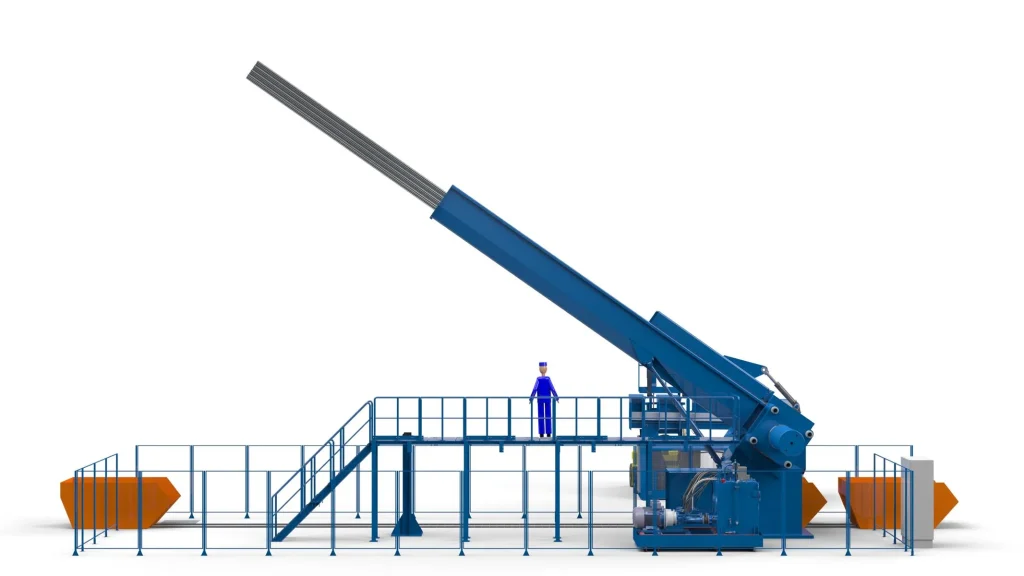

Long scrap shears: These shears are designed for pipes, rods, profiles, or billets up to 12 meters long and can be loaded with forklifts or indoor cranes.

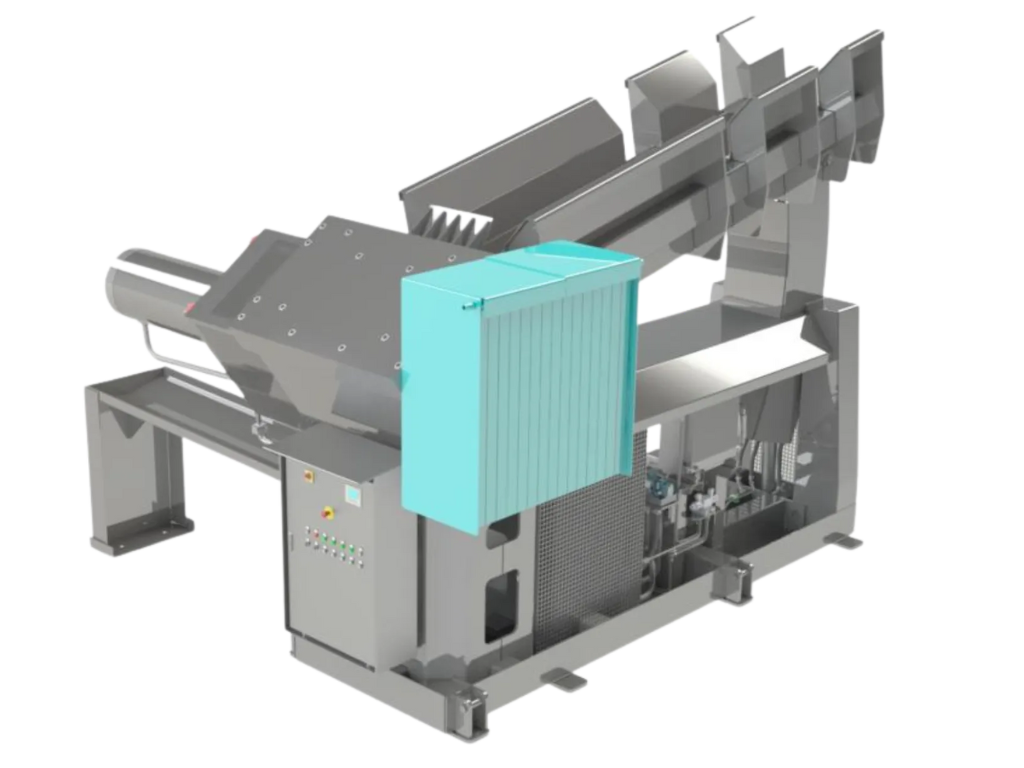

Press shears: Ideal for shredding rejects from die casting production. Compared to shredders, they produce fewer fine grains and have less wear. These shears can also be easily integrated into production plants as they can be loaded with forklifts.

Cathode shears or anode shears: Specifically designed for cutting up anode or cathode plates from copper or nickel electrolysis. Unlike traditional slitting and cross-cutting systems, these shears punch individual tile-shaped pieces from the plates in a single operation, which can be easily dosed as additives in the melting process.

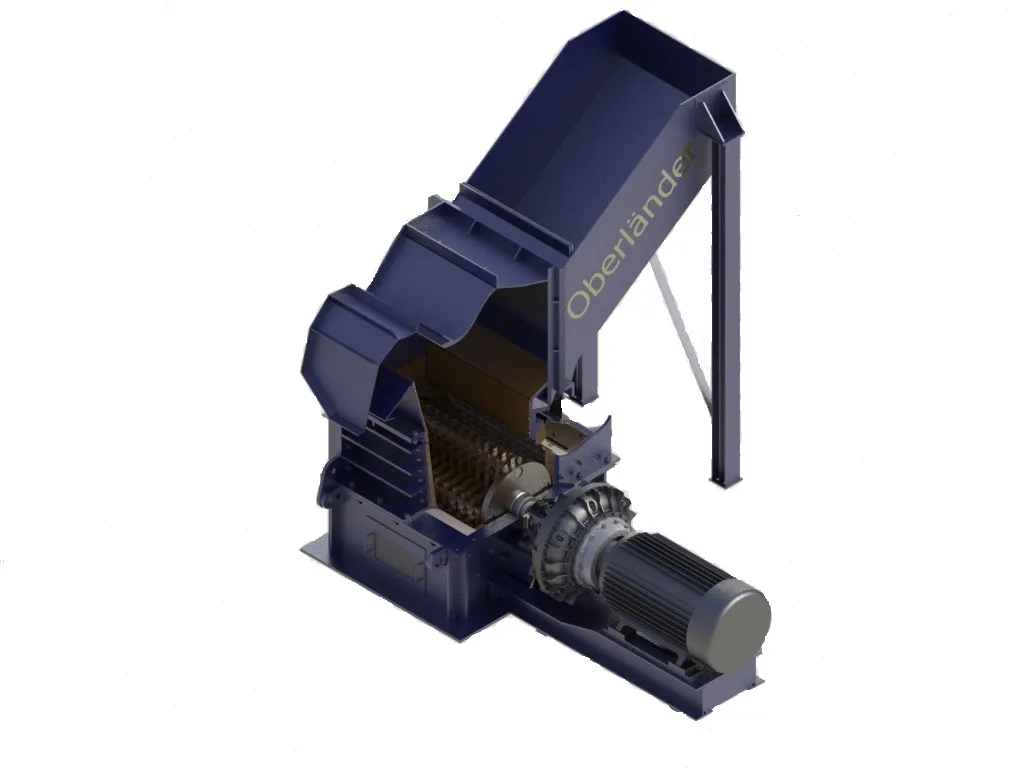

Cast crushers: These compact systems crush risers and reject parts from gray cast iron production. Compared to classic crushers, our systems are very compact and combine crushing and shearing processes.

We would be happy to offer you the right scrap processing system, just ask us.

Efficient scrap processing for production companies without material handling machines

Scrap processing in production companies that do not have the typical handling machines of recycling companies requires special solutions. Our special shears, presses, and crushers are designed to meet this need while ensuring efficient internal reuse of scrap and production waste.

1. Long scrap shears for versatile applications

Our product range includes a selection of long scrap shears that are particularly suitable for pipes, rods, profiles, or billets up to a length of 20 meters. These shears enable problem-free handling and can be loaded with both forklifts and indoor cranes. The versatility of these shears makes them the ideal solution for companies that rely on processing long goods.

2. Efficient shredding of aluminum die-casting scrap

For the targeted shredding of rejects from aluminum die-casting production, we offer special press shears that produce fewer fine grains and have less wear compared to conventional shredders. These shears are not only cost-effective but also require a small installation space. With the ability to set up directly next to the production facilities, internal logistics and storage costs for this bulky waste are eliminated. Reducing the proportion of fine grains increases the melt yield when reused in the production process.

3. Compact cast crushers for use in foundries

Compared to classic cast iron crushers such as jaw crushers, our press shears offer an efficient alternative that requires a small installation space and height. Even bulky long material such as risers can be effectively shredded to oven size. Because they can be loaded with forklifts or indoor cranes, they are easy to integrate into production plants. This flexibility enables smooth integration into existing processes without having to make major adjustments.

4. Anode shears

To shred electrolytically produced aggregates in metallurgy, anode or cathode plates are laboriously shredded to the dosage size in cross-cutting and slitting shears. Based on our experience in scrap processing, we offer simple, compact special shears that produce the desired panels from anode or cathode plates in just one processing step.

5. Custom-made scrap processing plants

Our commitment goes beyond the sale of classic scrap shears and presses - we also offer tailor-made scrap processing systems. Our experienced team is at your side to find the right solution for your specific requirements. Every business is unique, and we specialize in developing custom solutions that perfectly fit your needs.

6. Internal recycling means cost savings and emissions reduction

Not only the increasing logistics and handling costs make direct reuse in your own production company sensible, but also the high-quality reuse of your own alloys. This approach not only protects the commercial but also the CO2 balance of your company.

7. Dedicated customer service

Our customers value not only the quality of our products but also our dedicated customer service. If you are interested in our special shears or other scrap processing solutions, we are available to you at any time. We will be happy to answer your questions and help you choose the optimal equipment for your needs.

8. Sale, Rent, or Full Service Contract

We know that production companies are not always prepared for the maintenance and replacement of wearing parts in heavy processing systems, which is why, in addition to the normal service, we offer a rental or a full-service contract including all maintenance and wear and tear costs. Talk to us.

9. Training and support for optimal use

Not only do we offer high-quality scrap shears, but we also provide training and support to ensure you use your equipment to its full potential. Our experienced team is at your disposal to carry out training for operators or, for example, to carry out inspections according to the relevant safety regulations (UVV/BGV) of the equipment. This ensures long-term, smooth, and safe use of your processing plants and maximizes the return on your investment.

Conclusion: Your partner for efficient and sustainable scrap processing

Overall, our special shears offer a comprehensive solution for production companies that rely on efficient and sustainable scrap processing. With innovative technologies, tailored solutions, dedicated customer service, and a focus on environmental protection, we are your reliable partner in the scrap processing industry. Contact us today to find the optimal solution for your individual requirements and take your company to the next level of efficiency and sustainability.

Interested?

We have demonstration machines that we can also rent to interested customers. Ask for.