Stationary scrap shears

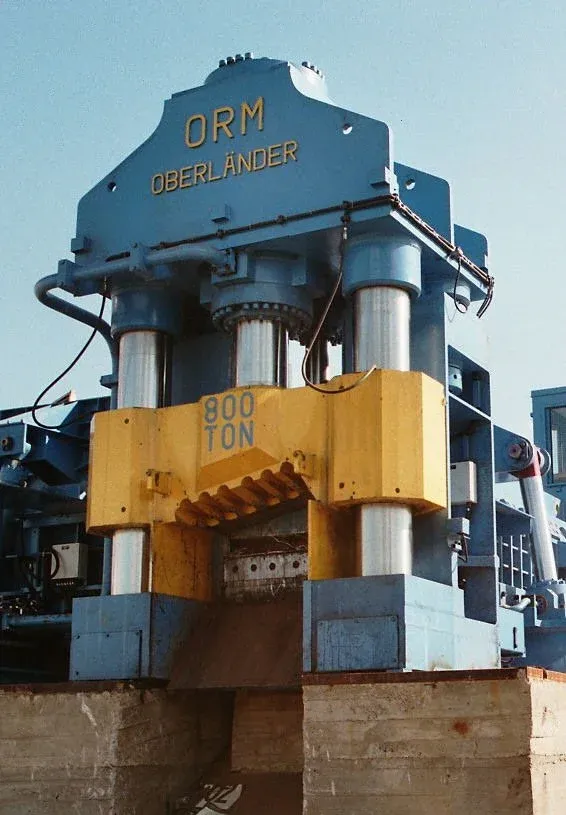

The Oberländer scrap shears are so-called press shears with side compressors that can also compress and shear heavy scrap, such as construction scrap or re bar bales. The Oberländer basic concept of the shear slider guide with columns, which has been tried and tested for more than 50 years, is the only type of guide that does not come into contact with the scrap or contaminants such as shear sand. The wear on the guides is therefore minimal and precise compliance with the cutting tolerance between the upper and lower blades is guaranteed for years. Adjustment of the guides is therefore not necessary, unlike linear or trapezoidal guides.

The Oberländer scrap shears are designed as a torsion-resistant welded heavy construction; this is reflected in the overall weight compared to competitor shears. This heavy design means that they can be installed without anchoring to the foundation and therefore keep foundation costs low.

Based on more than 50 years of experience in the design of scrap processing equipment, the latest generation of column shears incorporates many innovations that improve operating and maintenance costs and ease of use.

What's new:

Easy Maintenance: Shear and hold-down cylinders can be dismantled without removing the shear head.

Faster Cycles: Improved hydraulic control shortens pressing and shearing cycles.

Energy Efficiency: Power-controlled double pumps with low delivery volume during idling reduce power consumption.

Improved Hydraulics: Larger pipe diameters and optimized routing with fewer bends reduce pressure losses and waste heat.

Enhanced Comfort: Control chair in an air-conditioned cabin enhances ease of use.

Efficient Lubrication: Central oil and grease lubrication with large storage containers and easy access simplifies maintenance.

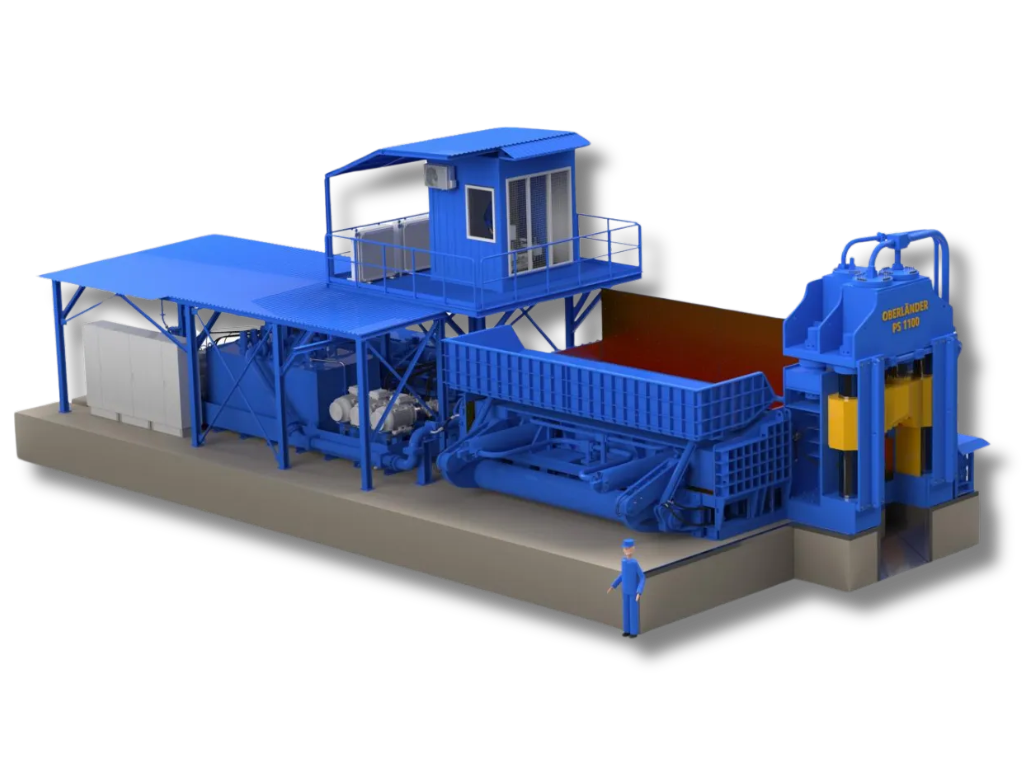

The basic concept of the Oberländer scrap shears with a Pre-filling trough, into which the scrap can be loaded while the guillotine shears are in operation, has proven itself and has been retained. This significantly reduces loading times, ensures easy sifting of contaminants and achieves a significant increase in production.

The mechanically processed press box enables precise movement of the compactors and fast, jam-free pre-compaction of the material.

Large-volume scrap is compacted effectively and easily with the help of the side compressor and a powerful, wide press lid that extends over approx. 2/3 of the press box width. The side compressor is guided via a synchronous shaft and ensures an even distribution of force across the width of the press box, without tilting the compressor. compacted effectively and easily. The side compactor is connected to a Synchronous shaft and ensures an even distribution of force across the press box width without tilting the compactor.

The particularly long down-holder guides allow the pre-pressed scrap by the side compressor to be moved against the lowered down-holder so that bales can also be produced with the shears.

Generously dimensioned hydraulic pipe and valve cross-sections, as well as straight pipe guides, allow for high hydraulic efficiency and low turbulence losses, which allows trouble-free operation of the shears even at high outside temperatures.

| PS 700 | PS 950 | PS 1100 | PS 1400 | PS 1700 | |

|---|---|---|---|---|---|

| Shearing force [t] | 700 | 950 | 1.100 | 1.400 | 1.700 |

| Press box length [mm] | 6.000 | 7.000 | 7.000 | 8.000 | 8.000 |

| Press box width [mm] | 2.000 | 2.350 | 2.350 | 2.500 | 2.500 |

| Side compactor height [mm] | 600 | 800 | 800 | 800 | 1.000 |

| Cutting width [mm] | 710 | 950 | 950 | 1.250 | 1.450 |

| Strokes per minute approx. | 4 - 5 | 3 - 4 | 3 - 4 | 3 - 4 | 3 - 4 |

| Hold-down force [kN] | 170 | 3.350 | 4.180 | 5.560 | 6.870 |

| Lid force [kN] | 1x 2.470 | 2x 1.710 | 2x 1.710 | 4x 1.710 | 4x 2.470 |

| Side compactor force [kN] | 1x 2.470 | 2x 2.470 | 2x 3.360 | 2x 3.360 | 2x 4.840 |

| Feed force [kN] | 1.250 | 1.250 | 1.250 | 1.710 | 2.470 |

| Cutting capacity [t/h]* | 15 - 20 | 25 - 35 | 28 - 40 | 32 - 45 | 35 - 50 |

| Main drive [kW] | 2x75 | 3/4x90 | 4/5x90 | 5/6x90 | 6/7/8x90 |

| Total weight [t] | 130 | 220 | 250 | 350 | 450 |

| * depends on the type of scrap and the cutting length | |||||