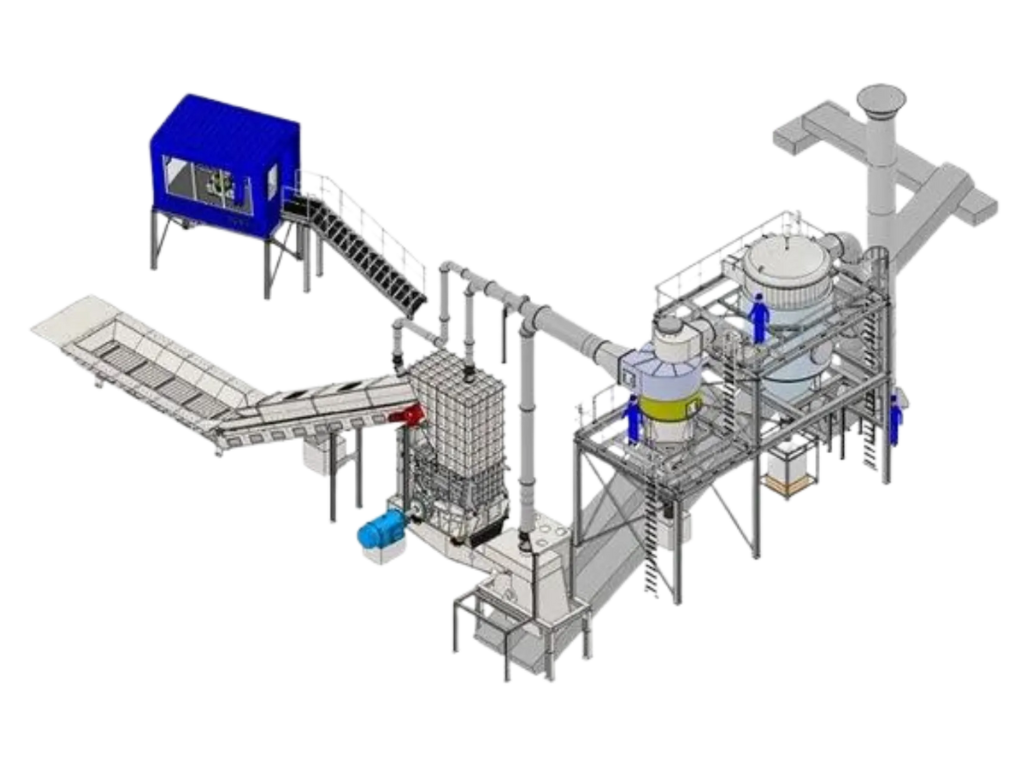

Aluminum Shredder Installation with star rings

In order to recycle aluminum scrap in remelting plants, or in the production of high-quality wrought aluminum alloys for producing aluminum profiles, impurities must be separated from the aluminum. These contaminants are in the form of iron alloys (e.g. fittings, screws, nails, rivets), copper components (cables, fittings), surface coatings (e.g. varnishes, anodized materials) and plastics (e.g. insulation, foil, handles) and wood.

Oberländer further developed the brass knuckles shredder in the 1970s, which has clear advantages over the hammer shredder that is used in steel scrap recycling. The rotating brass knuckles with sharp edges, compared to the hammer-anvil system, tear the material and thus break down contaminants better. By using a dry dedusting system, volatile components and dust are separated in the shredder and collected in a pre-separator in the form of a cyclone.

The explosion-proof, dry exhaust air purification system with ATEX approval offers clear advantages in terms of maintenance, operating and disposal costs for the filter fraction compared to wet scrubbers used by competitors. By using various digestion and separation processes, the system can recover high-quality aluminum raw materials with a high bulk density for use in melting furnaces.

The Oberländer aluminum shredder systems are characterized by high throughput, low operating costs and high availability. Compared to roller/shaft shredders, the star ring shredder is less sensitive to the unavoidable entry of contaminants, such as large pure aluminum parts, due to the evading of the star ring and the breakdown of impurities is better. The aluminum scrap processed in the Oberländer star ring shredder also achieves a higher bulk density than in other shredding processes, which brings clear advantages in the remelting process.

| Type | Model | Rotor Dimensions DxL | Drive Power |

|---|---|---|---|

| OST 1000/1250 | star ring | 1,000 x 1,250 mm | 200 kW |

| OST 1250/1500 | star ring | 1,250 x 1,500 mm | up to 800 kW |

| OST 1500/1500 | star ring | 1,500 x 1,500 mm | up to 1,000 kW |

| In addition to aluminum shredding systems, smaller systems for electronic scrap and heavy steel and cast iron shavings are also offered. | |||